Monolithics & castable

CASTABLES

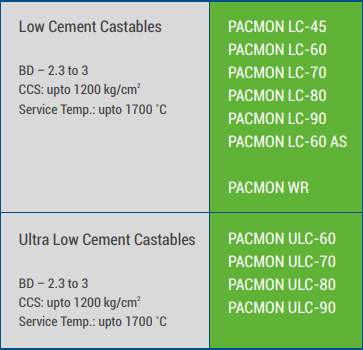

PACMON ™

(High Strength & Abrasion Resistant Low / Ultra Low

Cement Castables)

The range of Low Cement / Ultra Low Cement Castables are

ideal for applications requiring superior erosion resistance and

volume stability.

These are available with high density, lower porosity and

higher crushing strengths at all temperatures.

PACFLOW ™

(High Strength & Abrasion Resistant Self Flow Castables)

PACFLOW are self flowing castables which can be applied by

pouring or pumping to fill moulds or form work without

vibration.

They have low porosity, higher service temperatures & improved thermal shock resistance.

Ideal for quick installation in complicated locations as the material flows without the help of vibrations.

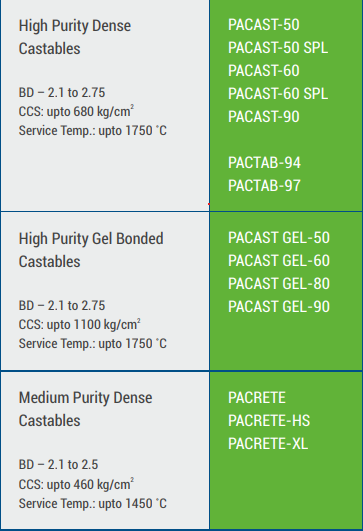

PACAST ™ / PACTAB ™ / PACRETE ™

(High / Medium Purity Dense Castables)

A wide range of dense castables in high & medium purity

varieties. These are used in various applications

by different industries.

Hydraulically bonded castables for high temperatures.

Based on alumino silicates, corundum & sintered aggregates.

Good impact strength. Minimum shrinkage.

High Resistance to abrasion. Excellent volume stability.

High purity Tabular Alumina Castables for stringent operating

conditions in Fertilizer, Refineries, Petrochemical industries.

These are ready to install refractories which develop superior

strengths on exposure to heat and under operating conditions.

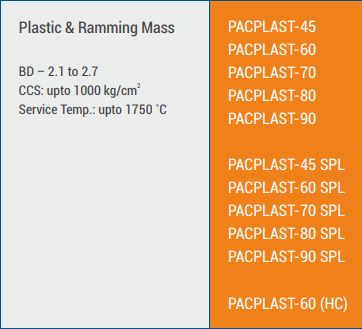

PACPLAST ™

(Plastic & Ramming Masses)

Refractory Plastics & Ramming Masses are monolithic

refractories, which develop good structural strength upon

exposure to heat.

Plastics are of semi-stiff consistency and are installed

primarily by pneumatic ramming.

Ramming mixes are similar to plastics but contain less

moisture, have less plasticity and can be placed by ramming

or tamping.

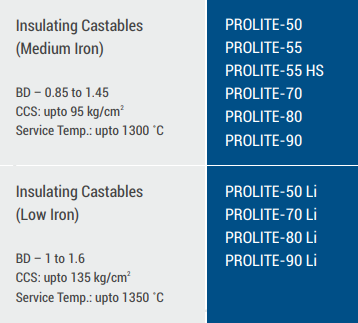

PROLITE ™

(Low & Medium Iron Insulating Castables)

A wide range of insulating castables in high & medium purity

varieties.

Minimum shrinkage and excellent volume stability.

Low Thermal Conductivity ensures minimum heat loss with

significant fuel savings.

Hydraulically setting, ready to install, these castables develop

superior strengths at operating temperatures.

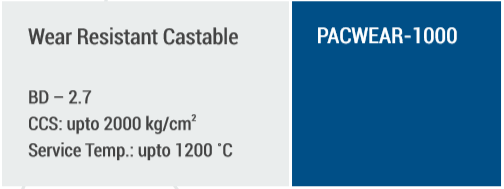

PACWEAR ™ (Wear Resistant Castable)

This castable offers superior wear resistance against heavy oer osion at elevated temperatures upto 1200C.

Suitable for use in cements plants.

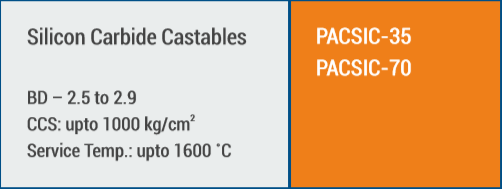

PACSIC ™ (Silicon Carbide based Castables

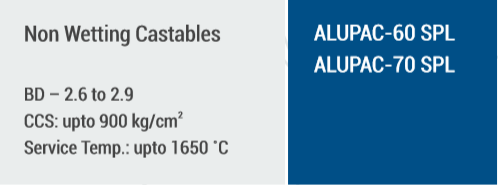

ALUPAC ™ (Non-wetting Castables for Aluminium Industry)

A range of castables ideally suited for Aluminium melting and holding furnaces.

Exceptional Resistance to wetting by molten Aluminium alloys. This results in longer refractory life, cleaner alloys & lower costs.

Superior erosion resistance, volume stability & better thermal shock resistance.